CompEx Ex11 has been created for mechanical engineers and fitters to gain a qualification in explosion safety to International Standards. CompEx EX11 is suitable for all personnel who may be required to break and isolate pipes to install or maintain Ex equipment such as pumps etc., and personal who may need to select, install or maintain Ex non-electrical equipment.

The course is designed to satisfy both the ATEX (European) and International (IEC) requirements. These standards require users to identify all possible ignition sources that could arise in hazardous areas. The identification of these ignition sources includes non-electrical (mechanical) items of equipment, covered in the EX11, as well as the electrical equipment covered by Ex01-04. The course covers the safety measures for non-electrical equipment used in hazardous areas, including safe selection, installation, maintenance, inspection and repair of the equipment.

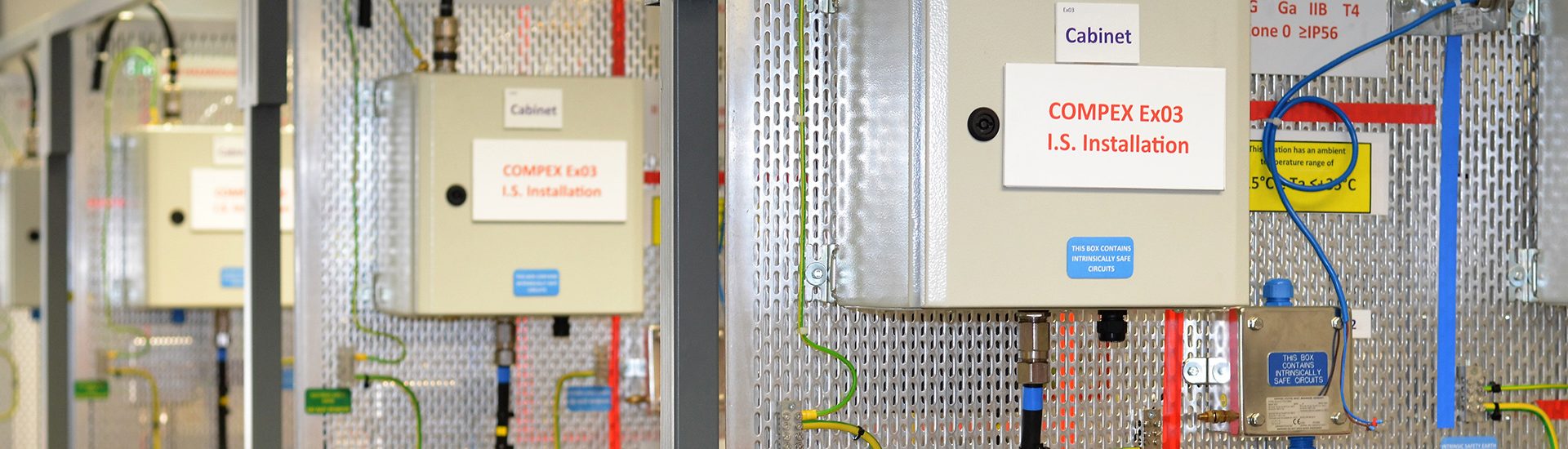

Delivery will be a combination of classroom tuition / and practical in the workshop.

Competence is assessed through:

Safety boots/shoes will be required, all other protective equipment and tools are provided