Professional inspection, servicing and certification you can rely on. We offer:

Subsea Riser inspection

Disassembly of Risers

- Removal of floats

- Removal of Auxiliary lines

- Removal of Jewellery

Inspection of Risers

- Visual and Dimensional Check on lines and main tubes

- NDT inspection on main tubes and lines

- NDT inspection on jewellery

Blasting and Painting of Risers

- Bare metal blasting on Flanges and welds of main tube

- Bare metal blasting on Auxiliary lines boxes and welds

- Sweep blasting on remaining Surface of lines and main tubes

- Painting with three coat system on bare metal and 1 coat system on covered surfaces

Reassembly of Risers

- Assembly of jewellery on Main tube

- Insertion of Aux Lines into Main tube

- Assembly of flotation modules onto risers

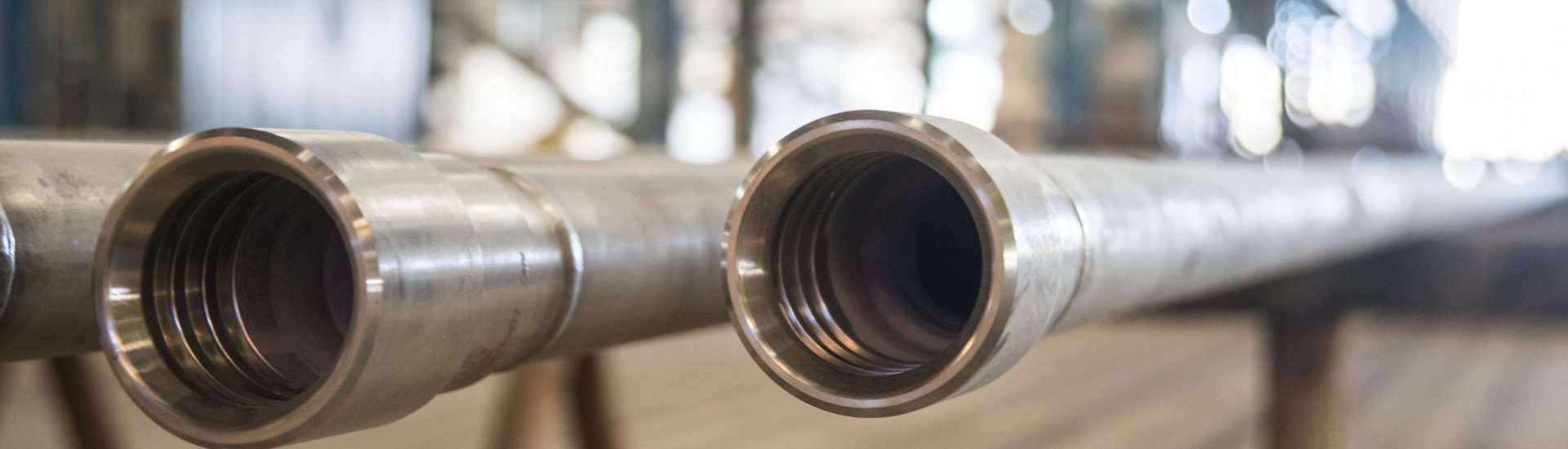

Drill Pipe inspection

Unbundling of drill pipes on pipe racks

- Lifting bundle on racks

- Preparation for washing

Cleaning of pin and box tool joints

- Mechanical and chemical cleaning at tool joint

- External high pressure washing

- Flushing of drill pipes

- Cleaning of thread protectors

Surface preparation for NDT

- Buffing of areas required to be inspected

Inspection of Drill pipes

- Visual inspection on tool joint face

- NDT inspection at tool joint and along joint

- Dimensional checks on tool joint

- Marking out and classifying joints post inspection

Repairs

- Re-facing on site following inspection

- Re-cutting of Damaged threads in workshop

- Hard band on tool joints.

Re-bundling of Drill Pipes

- Preparation for delivery to client